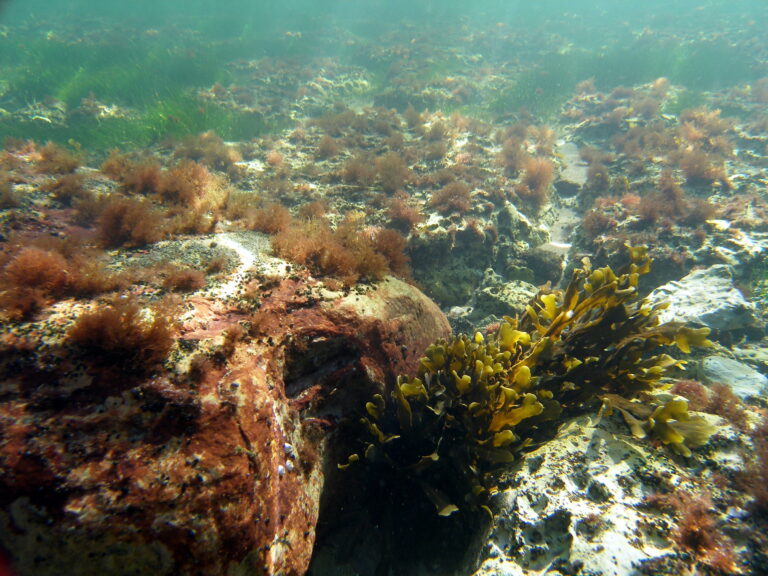

Furcellaria lumbricalis naturally grows on the rocks in the sea bottom, usually up to 20 meters below the sea level. However, if the water is clear, then even up to 30 meters below the sea level.

In the Baltic Sea there are two different forms of Furcellaria lumbricalis: attached and loose-lying (drifting) thallus forms. Thallus is brownish-black coloured and the cluster contains straight, narrow, sharp apiece stalks. Which has given it a nickname of clawed fork seaweed.

Drying seaweed using natural resources like the sun and wind is a traditional and effective method that has been used for centuries. It is a sustainable and eco-friendly way to process seaweed. Once the seaweed mass is sufficiently dried, it will be moved into a controlled environment into Est-Agar seaweed shed.

Dried seaweed is collected into Est-Agar seaweed shed, where it will be stored until moving on to production line. Before production process there are different quality checks that will be conducted.

Factory has fully equipped laboratory for daily quality checks. Each batch of furcellaran is always carefully tested to make sure the quality is according to standards.

Innovation is in our hearts as well, we are constantly finding new areas, where furcellaran can be used. In the gallery you can see lamps made by Estonian Academy of Arts out of furcellaran.

Furcellaran is used in many beauty products, serving different purposes.

Texture enhancement: Furcellaran is a hydrocolloid, which means it can absorb water and form gel-like substances. It can help provide a smooth, luxurious texture to creams, lotions, and other cosmetics, enhancing the overall sensory experience for users.

Vegan-friendly alternative: Furcellaran serves as a plant-based alternative to traditional anima-derived texturants. Making it suitable choice for vegan and cruelty-free beauty products.

Antioxidant properties: One of the most significant benefits of furcellaran derived from red algae is its natural antioxidant properties. Antioxidants help protect the skin from oxidative stress and free radicals.

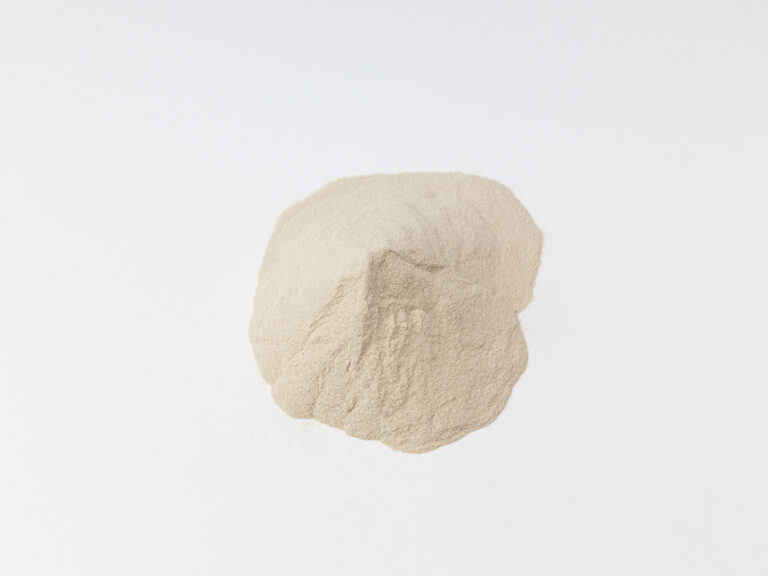

Est-Agar produces furcellaran in two different forms: flakes and powder. There are two different production lines set up in the factory. Powder is the newest addition, having innovative and well automated production technology.

There are slightly different applications for both forms. We have outlined the best application areas in the application section.

Furcellaran flakes and powder are packed into 10 kg and 20 kg paper bags respectively that will help to preserve the quality of furcellaran. Bags are packed into pellets for smooth and safe transportation.

However, in case different quantity is needed, make sure to contact us and we can adjust it according to your need.

Est-Agar is constantly moving towards sustainable production process to emit less waste and emission. There are already many practices in place to reduce factory footprint. We have implemented conservation techniques to use less energy and water in the factory. We are using clean energy from solar panels. Production process is built on maximising the value of seaweed, hence even the production residue is valorised – at the moment it is used in agriculture as natural fertiliser, however a new product is under development in the form of biodegradable seaweed herb growing pots.

Factory is located in Kärla, Saaremaa middle of the thick woods and deep blue sea. Even though, the factory building has a long history, we have modernized the factory, providing breathtaking surroundings and comfortable work environment.

Company values zero waste manufacturing in every aspect by promoting a manufacturing system that utilises minimum materials, generates minimum waste and also valorising production waste. Currently all production waste is used in agriculture as a natural soil fertiliser. However, there is an innovative product in development in the form of biodegradable, natural planting pots for industrial use. Planting pots will replace plastic pots currently used by herb growing companies.